Our Capabilities

- Floor plan

- Interior Elevations

- Exterior Elevations

- MEP As-Built

- Reflected Ceiling Plans

- Furniture, Fixtures, and Equipment (FF&E) Schedule

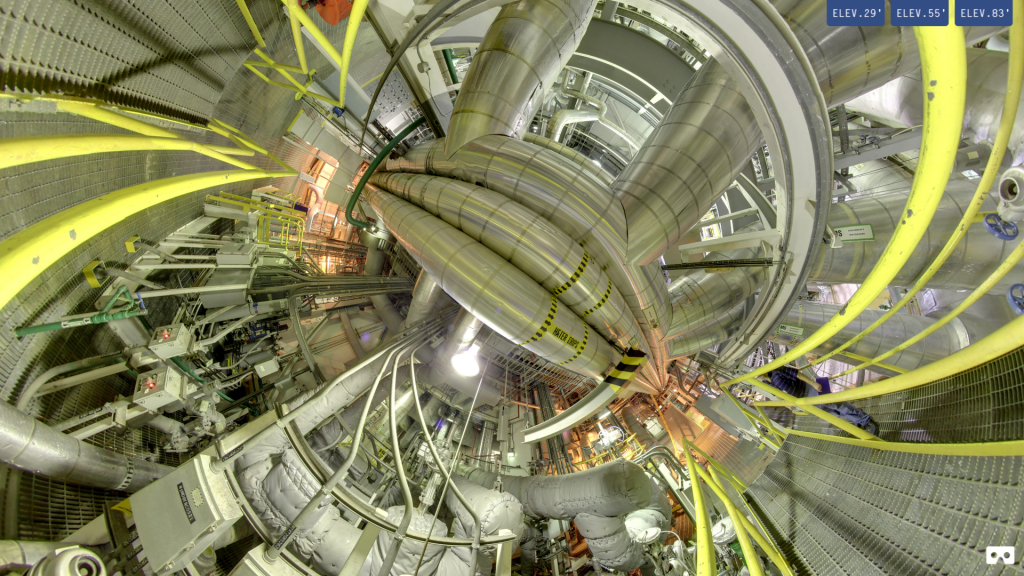

- Panoramic Imagery imposed on a floor plan (16K Pixels in Resolution)

- Interactive 3D model of the space- Virtual Reality Ready

- 3D Renderings

Our Experience

Accurate floor plan measurements for architectural renovation reduce the overall project cost, and help stakeholders make timely decisions. We eliminate the hassle associated with measurements and documentation of existing homes.

We use 3D Laser Scanning devices that can measure the surrounding walls, doors, windows and roof. All the data is then taken back to the office and imported into CAD to generate precise 2D and 3D drawings.

What to Expect

- A survey performed by Engineers

- Most accurate 3 dimensional measurement devices on the market today

- Top-notch realistic as-built survey delivered in 3D and 2D CAD format

Software

Our Process

This will be general information about the project including address, building size, occupancy status, etc.

What are we expected to deliver? The answer to this questions helps us draft the SOW. For example, are we delivering a Pointcloud file, Revit, ArchiCAD, or DWG files of the existing building? Are we documenting Furniture, Fixtures & Equipment (FF&E), or only Architectural As-Built.

Are there any specific safety concerns about site access? Understanding your schedule constraints will help us assign and manage resources in order to meet your deadline. We are committed to maintaining a safe and healthy environment for our employees, contractors and clients. Any safety concerns will be addressed during this stage.

Information from steps 1-3 above are used to generate a proposal and coordinte schedule, site visit, and data collection.

During this step, we perform a quality check on the data gathered in the field and ensure that measurements are accurate. We are also able to quantify how accurate the data is at this stage. A data registration report could be provided to the client upon request.

The collected data is imported into the appropriate software and vector files are generated.

Generated CAD model is overlaid on top of the pointcloud data and any shifts/anomalies are identified, quantified and repaired. Uncertain measurements are called out on the drawings to help you make the final judgement.

Case Study