Our Capabilities

- Rail As-Built Surveys

- Mobile LiDAR (Hi-Rail)

- Ballasts Quantification

- Slope Analysis

- Track Geometry

- Horizontal & Vertical Alignments

Have Questions?

Our Experience

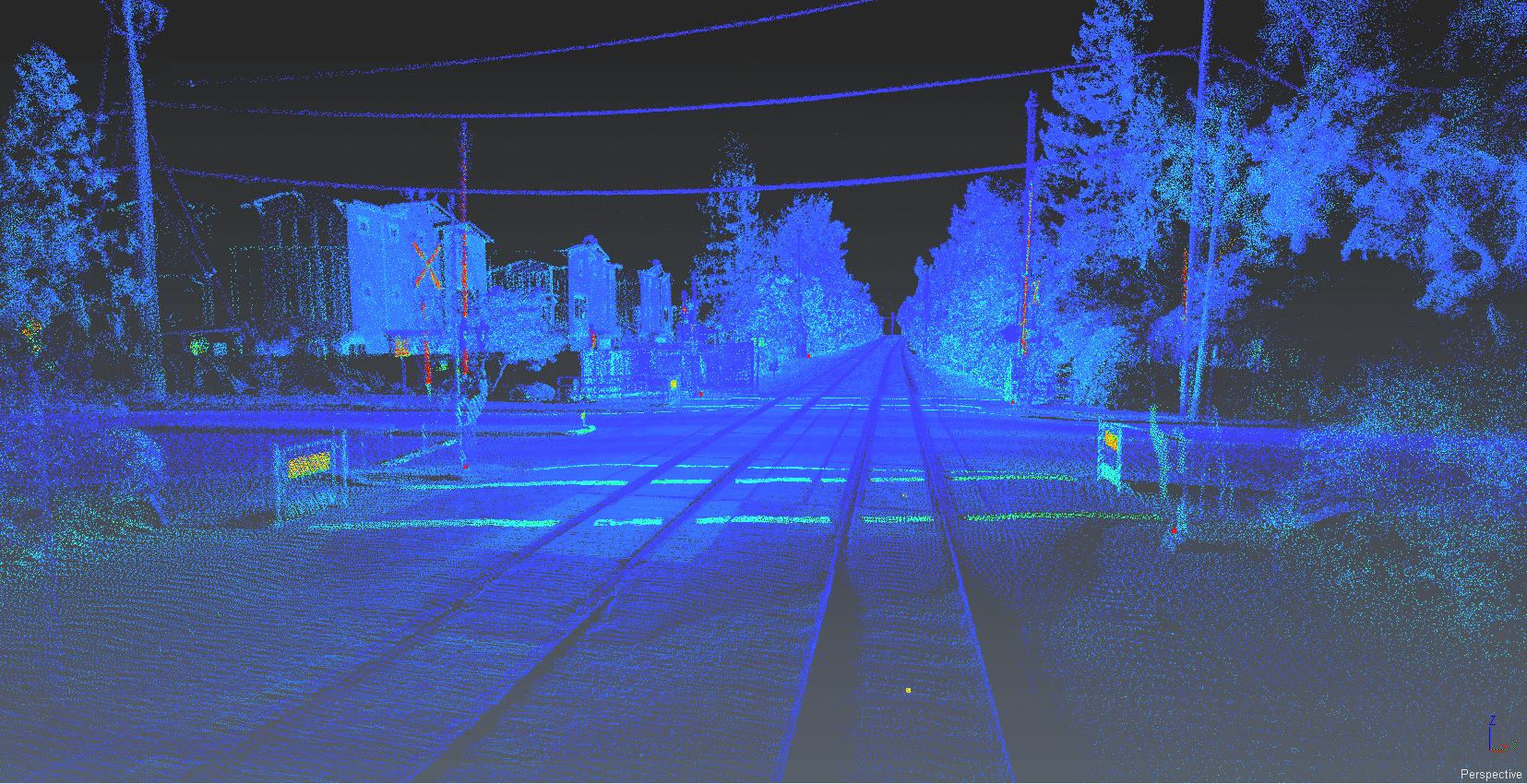

Reality IMT supports the Rail and Transit industry nationwide by providing mobile mapping services that can digitize the above ground surface within the entire Right of Way (ROW). We apply the latest technology tools to document and measure hundreds of miles of corridors without disturbing traffic.

Our LiDAR mapping device is used to collect millions of measurements on the fly with high level of accuracy. All measurements are geo-referenced to a local coordinate system that can be verified by our client’s survey crew post mission. In addition to 3D laser measurements, we utilize a 3D camera that can provide an ultra high resolution image of the corridor in 360 degrees. Our Rail 3d mapping services enhance engineering accuracy, shorten project schedules, eliminate safety hazards of field crew, and reduce costs associated with multiple site visits. Maintenance and operations teams can improve coordination among the each other, among contractors and suppliers by using a web-based 3D as-is environment showing the exact layout of tracks, signals, junction boxes, grade crossing and more.

Our clients are able to reduce time spent on the project by 40% and reduce cost by 25% when compared to conventional methods.

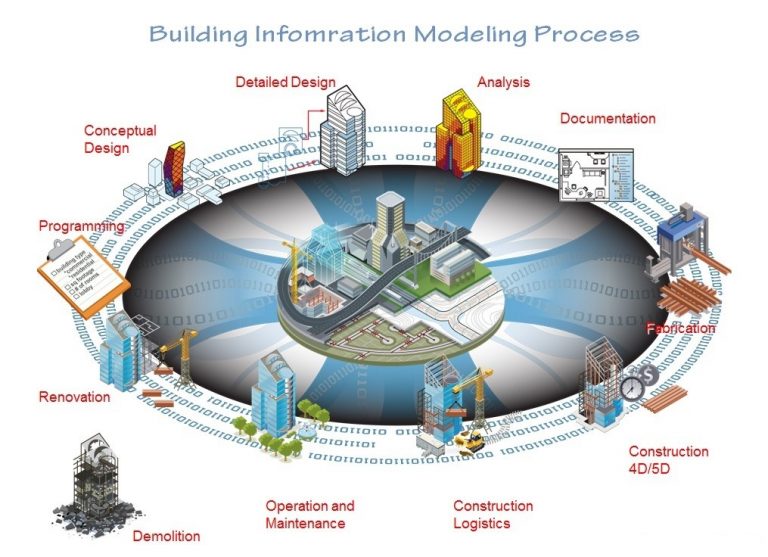

Our Process

This will be general information about the project location, point of contact, area of interest, etc.

What are we expected to deliver for the Rail network? The answer to this questions helps us draft the SOW. For example, are we delivering a Pointcloud file, MicroStation, GIS, DWG, 3D imagery or 360 video with GPS? What assets are you interested in locating within the ROW?

We are committed to maintaining a safe and healthy environment for our employees, contractors and clients. Any safety concerns will be addressed during this stage. Working with your team, we identify any health and safety risks associated with delivering the project and plan mitigation. We ensure that draft permit forms and JSAs are ready before deploying personnel. In this stage, we also discuss any schedule constraints you may have and communicate weather or not we are able to safely meet your deadline.

Information from steps 1-3 above are used to generate a proposal and coordinate schedule, site visit, and data collection. A detailed approach will be listed and discussed with the client. Once approvals are received, resources are deployed and data collection starts in the field.

During this step, we perform a quality check on the data gathered in the field and ensure that measurements are accurate. We are also able to quantify how accurate the data is at this stage. A data registration report could be provided to the client upon request.

The collected data is imported into the appropriate software and vector files are generated.

Generated CAD model is overlaid on top of the pointcloud data and any shifts/anomalies are identified, quantified and repaired. Uncertain measurements are called out on the drawings to help you make the final judgement.

Case Study