Offshore 3D Laser Scanning & Modeling

3D laser scanning as a service for offshore and on-shore facilities can acquire millions of measurements that are referenced to a local coordinate system. The measurements are then connected to a single 3D environment in the form of pointcloud data. The pointcloud data is then imported into CAD modeling software to generate surfaces and vector files.

3D Laser Scanning and oil and gas mapping for your facility are ideal before and after retrofitting, and before and after upgrading piping, valves, furnaces, etc. It can accurately capture dimensions of the surrounding environment and enhance operational efficiency, reduce cost, and eliminate workarounds.

Located in Houston, Texas, Reality IMT provides 3D Laser Scanning and 3D CAD Modeling services to EPC (Engineering, Procurement, and Construction) companies, as well as to owner-operators, in the oil, gas, petrochemical, refining, and pipeline industries. From hydrocarbon transportation projects to complex production rigs and refinery revamps, Reality IMT can help you plan your upgrades and maintenance more efficiently by providing an up-to-date, as-built laser scan of your assets. We are engineers, not technicians, and understand what it takes to safely get accurate, reliable data.

Offshore As-Built Services Include:

- Topside Documentation using High Resolution Panoramic Imagery

- 3D As-Built Laser Scanning and Pointcloud generation

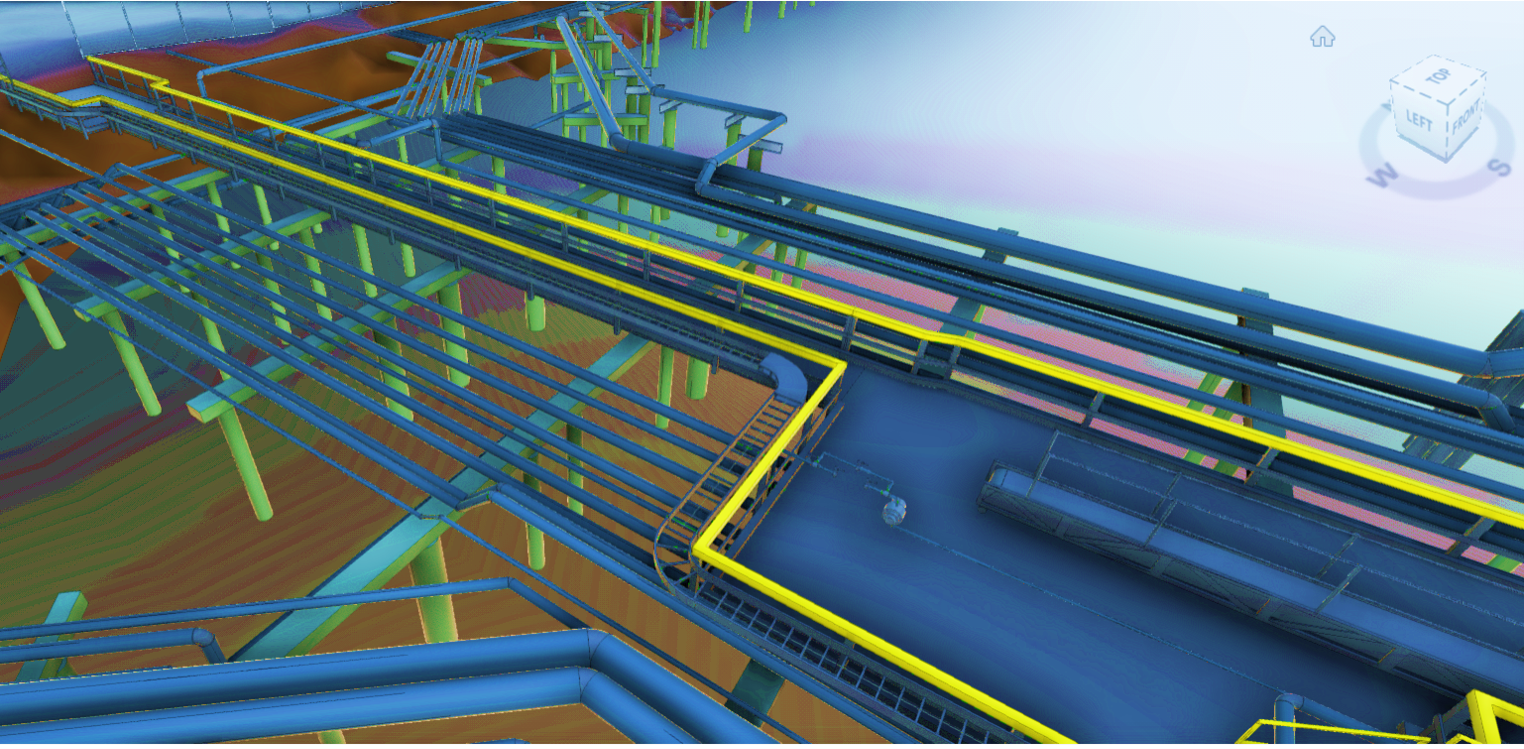

- As-Built BIM for facilities nationwide

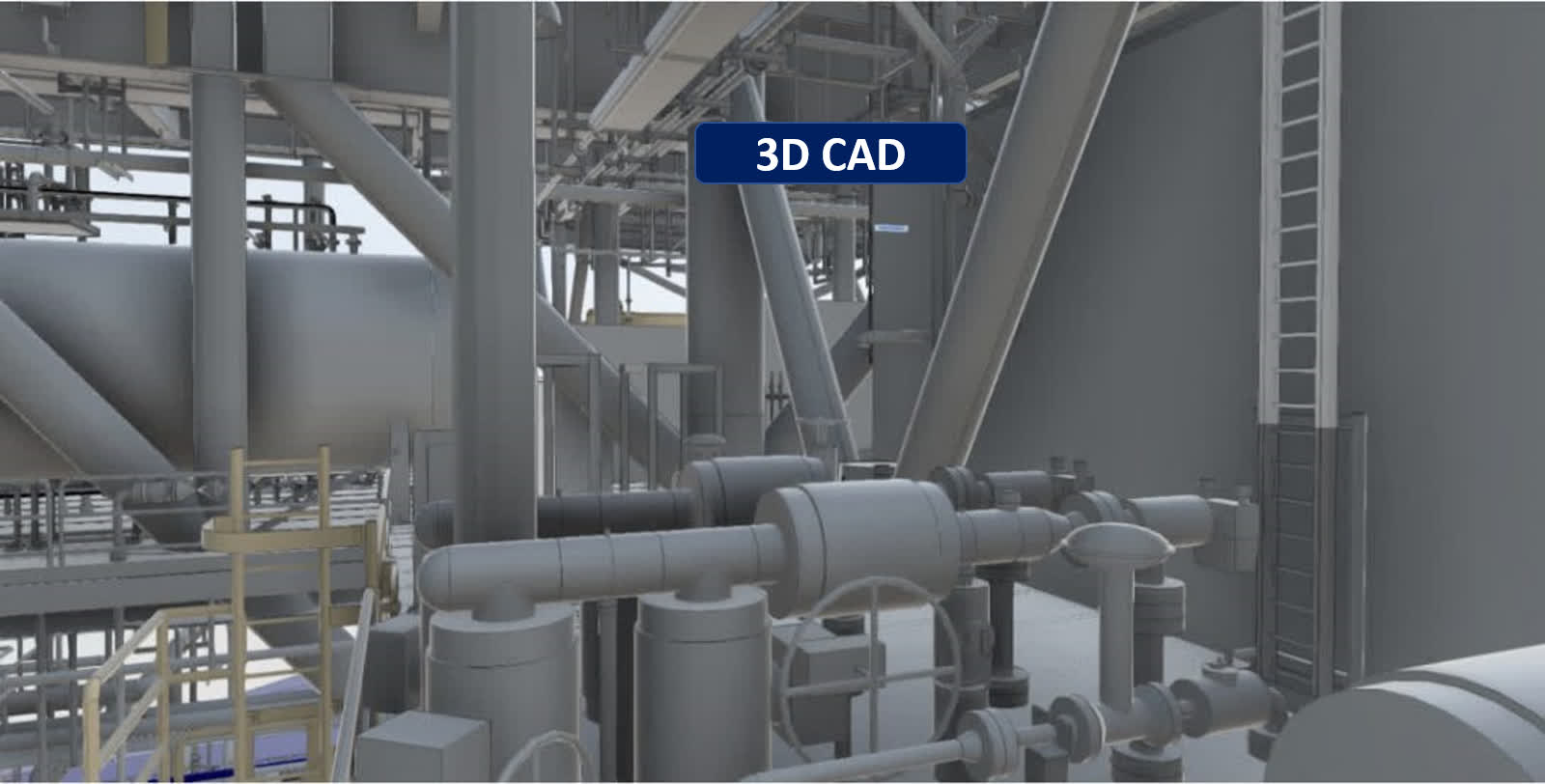

- Intelligent 3D CAD Models

Get Accurate As-Builts of the Entire Facility

The boom and bust of oil prices demand diligent oversight in the planning and implementation of energy capital improvements. Now more than ever, upstream, midstream, and downstream brown field oil and gas capital investments must be managed wisely to more precisely forecast budgets, control costs, maintain schedules, and improve returns.

The foundation for success in oil and gas construction is to integrate up-to-date, fact-based imaging data with 3D as-built laser scanning of your facility, and creating an as-built Building Information Models (BIM) for revamping refineries, building pipelines, and retrofitting rigs.

Petrochemical 3D Laser Scanning & BIM

Located in Houston, Texas, Reality IMT provides 3D Laser Scanning and CAD Modeling services to EPC (Engineering, Procurement, and Construction) companies, as well as to owner-operators, in the oil, gas, petrochemical, refining, and pipeline industries. From hydrocarbon transportation projects to complex rigs and refinery revamps, Reality IMT can help you get accurate, up-to-date as-built laser scanning of your entire facility.

Petrochemical As-Built Services Include:

- Digital P&ID

- 3D Laser Scanning and Pointcloud generation

- As-Built BIM of your facility

- Intelligent 3D CAD Models and Isometrics

- High-Resolution Panoramic Imagery

Plan Maintenance and Compliance More Efficiently

- Up-to-Date P&ID: In many instances, project managers and operators do not have an up-to-date P&ID. Our team can help you digitize your P&ID to streamline engineering and maintenance, without worrying about out-of-date or non-existing lines.

- Smart Plant: 3D Laser scanning can provide a digital replica of the entire plant layout with accurate geometry, dimensions, and location. As you continue to upgrade your plan, 3D laser scanning and 3D CAD modeling of the as-built environment will become the basis for the Smart Plant of the future.

- Material Takeoff: As-built 3D models can streamline the bid tabulation and procurement process by providing contractors with a digital inventory of the assets leading to more accurate pricing and delivery schedules.

- Visual Asset Documentation: High-Resolution Panoramic Imagery is typically collected with laser scans to help produce a virtual walkthrough of the site. The walk though eliminates the need for multiple site visits and keeps non-essential personnel safely out of the site, leading to a safer operation, reduced cost, and increased efficiency.