In the past, creating accurate measurements for an existing building or large industrial complex was a challenging and time-consuming process. But with the introduction of reality capture technology, that process has become much more streamlined and efficient. In this blog post, we’ll take a closer look at how reality capture is changing the design/build workflow and explore some of the key benefits that come with this technology.

What is Reality Capture?

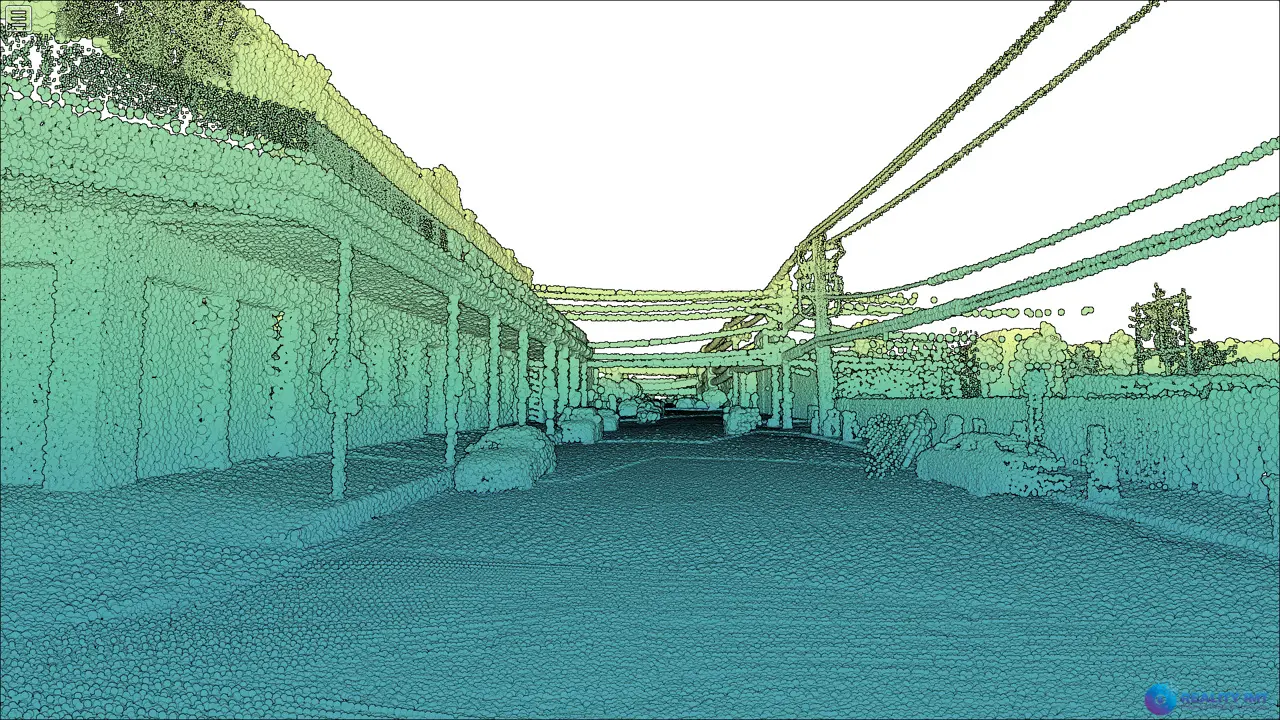

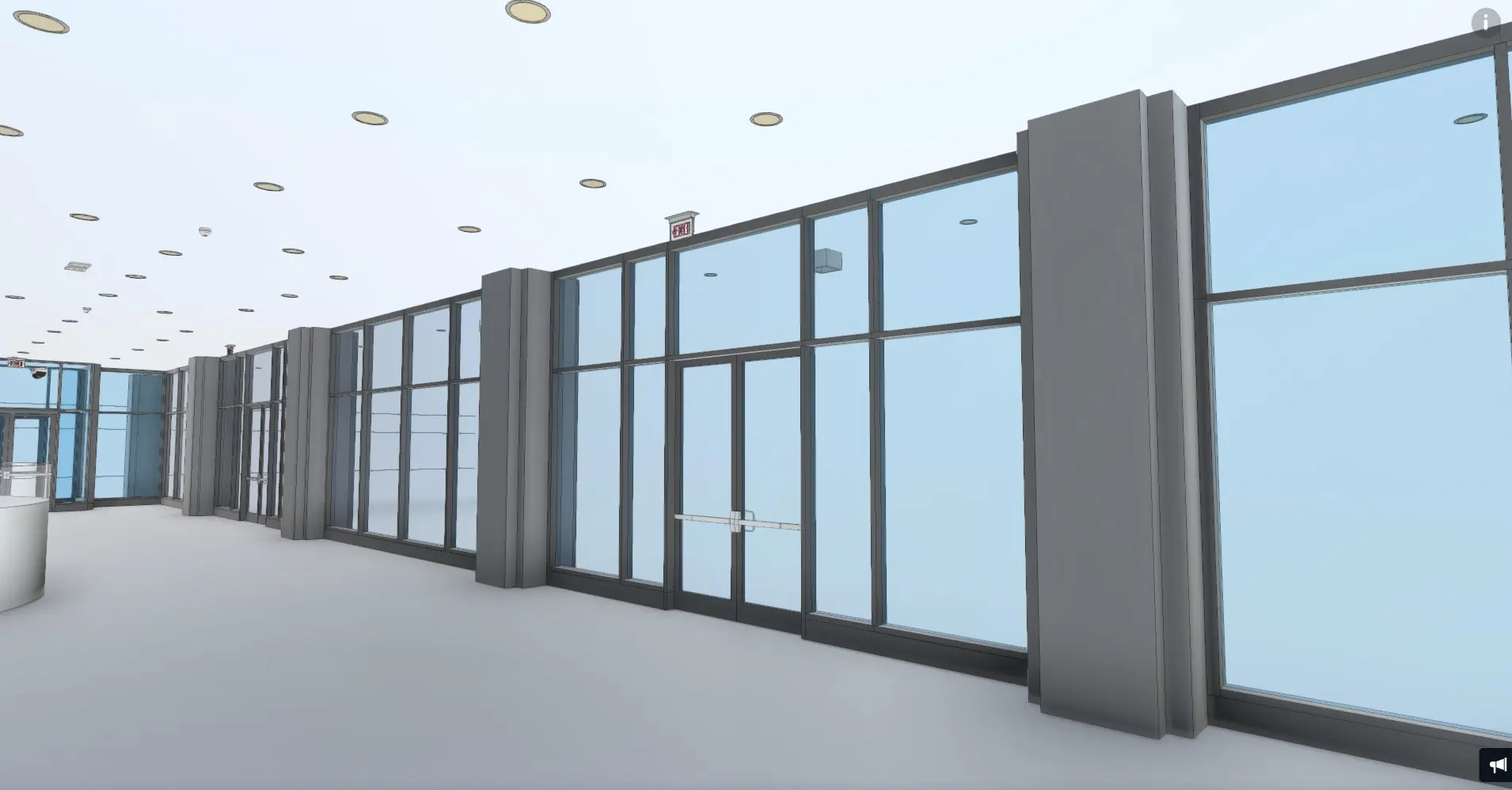

Reality capture refers to the process of using 3D laser scanning, photogrammetry, and other technologies to create a highly accurate digital model of an existing structure or space. This model can be used for a variety of purposes, including design, planning, and maintenance. It provides architects, engineers, and builders with a detailed understanding of the structure they are working with, which can help to minimize errors and streamline the entire design/build process.

Benefits of Reality Capture

There are many benefits to using reality capture in the design/build process, including:

-

-

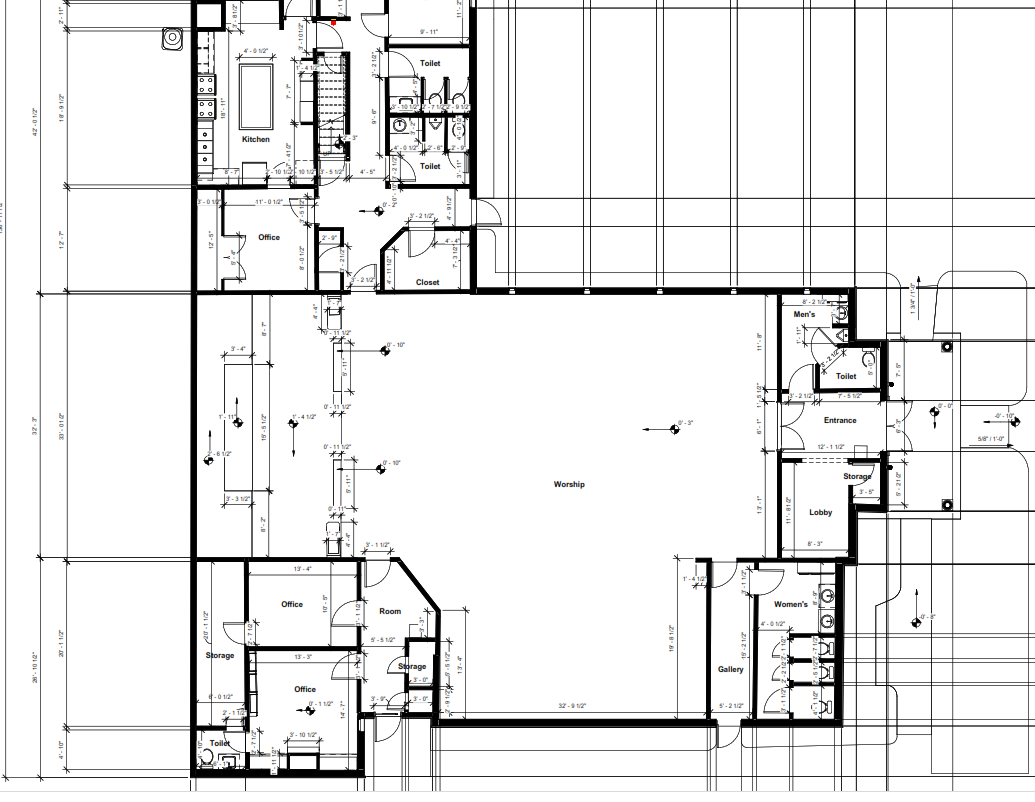

- Accurate As-Built Drawings: One of the most significant benefits of reality capture is that it can provide highly accurate as-built drawings of an existing structure. These drawings can be used for a variety of purposes, such as retrofitting, expansion, or repair work.

- Material Takeoff: As-built 3D models can streamline the bid tabulation process by providing contractors with a digital twin image of the facility. This leads to more accurate pricing and delivery schedules.

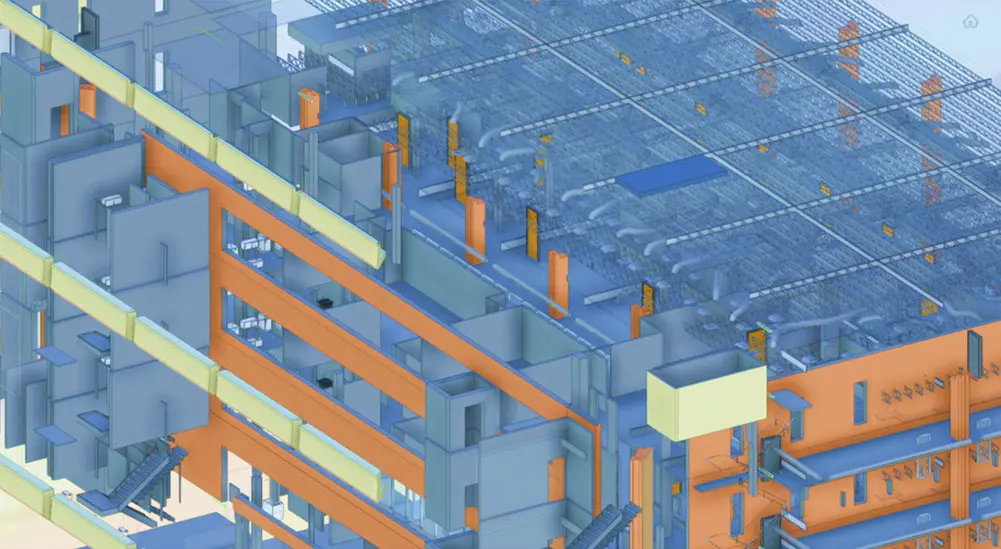

- Visual Asset Management: Laser scanning can digitize entire facilities in 3D photogrammetry. The scan results can then be deployed on the intranet using visual asset management software, where all maintenance documents can be aggregated and linked to the digital 3D models.

- Smart Plant: Laser scanning provides a digital twin of the facility. 3D models can become intelligent when linked to selected types of operation or maintenance data using IoT. For example, a tank 3D model can be used to simulate volumetric changes in real-time based on data received from the field.

- Efficient Workflow: Reality capture technology has made the design/build process much more efficient. By providing highly accurate measurements and detailed information about the structure, architects, engineers, and builders can streamline their workflow and minimize errors.

-

Reality Capture Technology

Reality capture technology typically involves the use of 3D laser scanning, photogrammetry, or a combination of the two. There are many different types of scanners and equipment used in reality capture, including LiDAR, which can be used for maintaining the piping system within industrial plants.

Costs and Performance

Reality capture requires a trained technician to spend time on-site to capture enough images of the structure being scanned to create an accurate 3D model. More time is required to drive lower margins of error as well as capture larger and more complex structures. The time spent on-site would create a point cloud, which is a “Raw Image.” Additional time would then be spent by a CAD designer to move the raw image into a CAD model. While the process can be time-consuming, it can ultimately save time and money by minimizing errors and streamlining the design/build process.

In conclusion, reality capture is a valuable tool in the design/build process, and its benefits are many. By providing highly accurate measurements and detailed information about existing structures, reality capture can streamline the entire design/build process, minimize errors, and ultimately save time and money. As reality capture technology continues to evolve, it will undoubtedly play an increasingly important role in the design/build process.