Hopper Volumetric Survey

Performing a hopper volumetric survey to understand it’s capacity is not only crucial for project planning, but also for cost estimates and scheduling. When parties cannot agree on the actual volume of a dredger, a laser scan or a LiDAR survey becomes the answer. If you go off of the manufacturer’s published volumes, you might not be getting the exact measurements you need to properly plan and budget for your project quantities. A simple LiDAR survey can save millions of dollars in project cost as it will provide précises measurements of the total volume, this volume is then used as the baseline for planning production rate.

Project Information

Existing sand dredger operating in the Gulf of Mexico.

Window of Opportunity: 4 hours while the dredger is docked for maintenance. Wet, muddy and slippery surfaces. Crawling inside the hopper area to scan it will be needed.

Requirements for Hopper Volumetric Survey

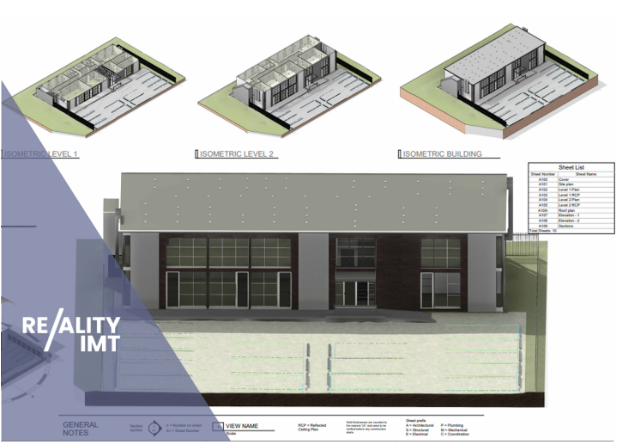

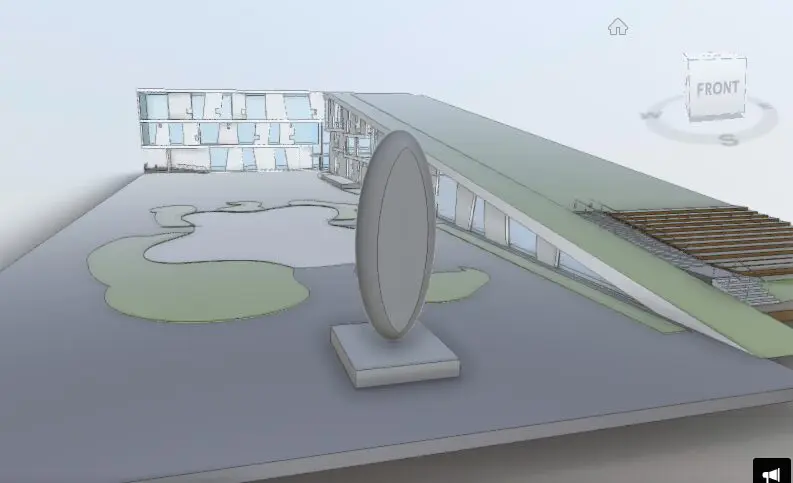

Measure the inclined walls of the hopper area inside the dredger. Develop a 3D model and isometrics in CAD. Perform volumetric calculations every 10 feet form the bottom to the top.

Project Duration: 1 day in the field. 8 days modeling.

Deliverable: 3D DWG + Excel Sheet with volumetric intervals & simulation video.

Technology Used: 360 laser scanner, AutoDesk, Excel.

For more info on 3d laser scanning service, click here