Industrial As-Built Survey

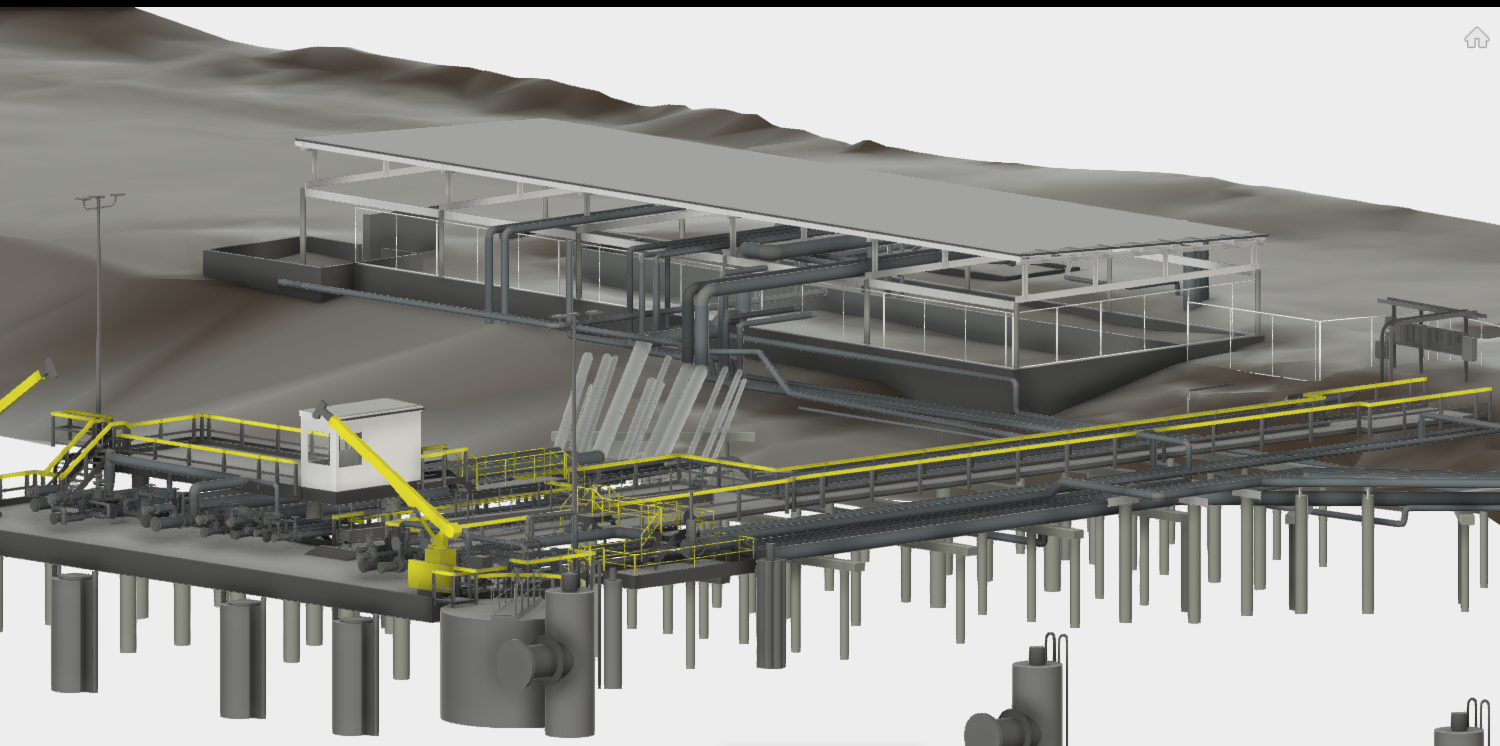

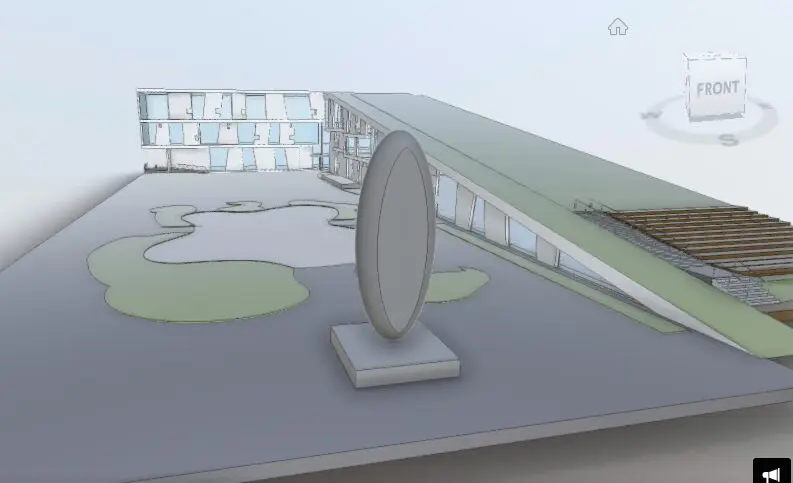

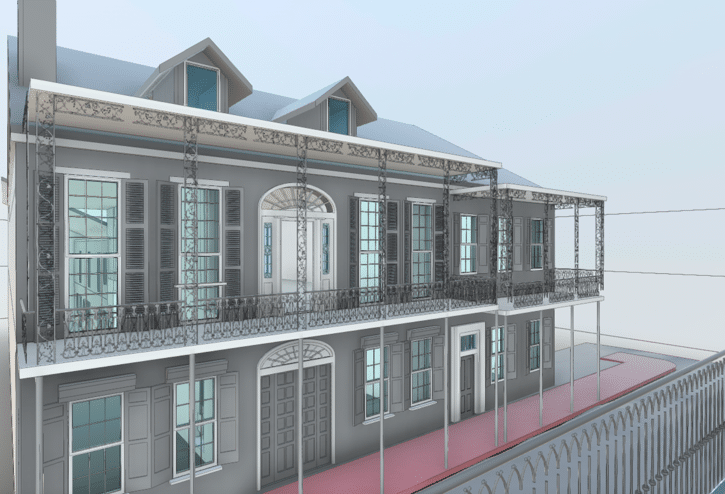

While a conventional as-built surveys may provide hundreds of data points for engineering maintenance, a 360 degree laser scan survey provides billions of measurements. When taking multiple setups and connecting the data points (pointcloud) together, a digital twin of the entire site is created. This eliminates any site revisits, provides engineers with all measurements needed for their design, increases efficiency and most importantly, it is more fun to work with. LiDAR surveys stand for Light Detection and Ranging is a method used to determine distance of objects from a device that emits laser in all directions at high speed, sometimes reaching to 700,000 beams per second, or another words, 700,000 measurements per second. The shear size of the captured data provides an accurate depiction of surface geometries, which then helps engineers model the exact dimensions and shapes of objects as in real life.

Project Information

Industrial Ship Dock located in Houston, Texas. Use: Offloading Terminal for Oil Products.

Requirements For an Industrial as-built Survey

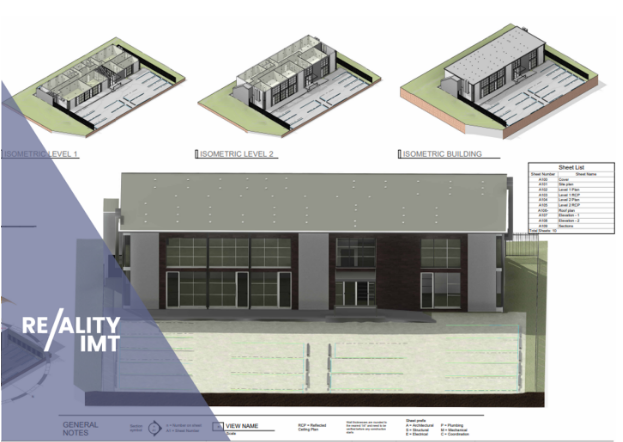

Perform an as-built measurement survey to include pipes, pumps, dock, seabed elevations, above ground structures including buildings and fence. Project Duration: 1 day in the field. 10 days in the office. Deliverable: 3D As-Built DWG, and PDF Technology Used: 360 laser scanning and AutoCAD.

For more info on 3d laser scanning service, click here