As technology continues to evolve at a rapid clip, old standards are slowly giving way to newer options. Vehicles, for example, are increasingly electric, and charging ports are a normal part of life in large swaths of the country. It might seem like the transportation industry in general has been overhauled and replaced with state-of-the-art technology, but that’s not quite the case. In fact, one of the most important methods of transportation in the United States remains one of its oldest: railroads.

Since their invention in 1797 to their first appearances in the U.S. in 1827, and even through their “golden age” beginning in 1865, railroads have been critical infrastructure to the country. From passengers to freight, railroad tracks help the country function. Today, more than 40% of all U.S. freight is hauled by train – and the number is rising. For railroads to function as intended, the tracks must be kept in good condition, and railway right of way must be observed.

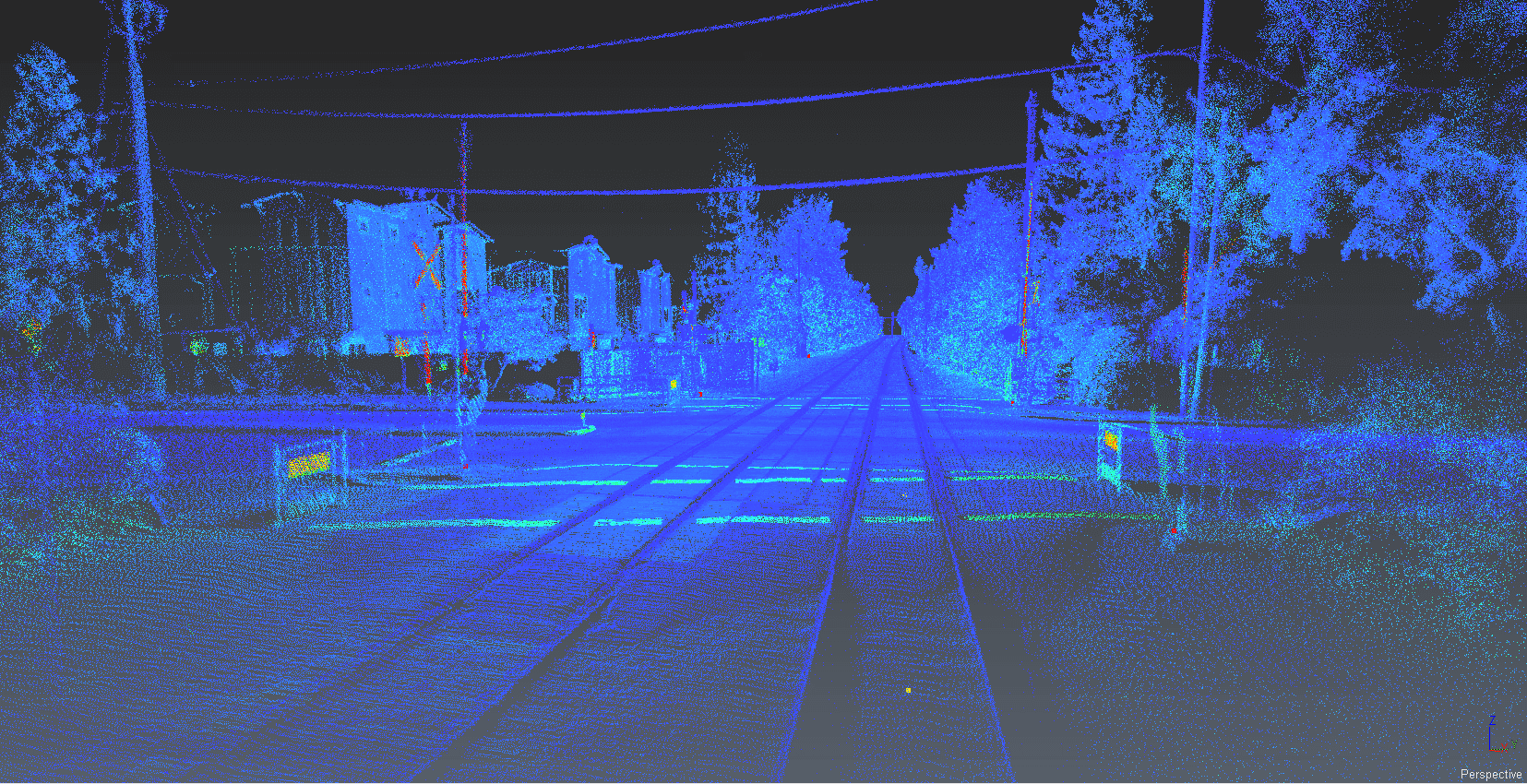

At Reality IMT, we understand the importance of proper track and right-of-way maintenance. We collect photo and video documentation as well as survey data using hi-rail vehicles and our LiDAR mapping system (with a 360-degree camera) to make maintaining, managing, and planning railway right of way easy. Let’s take a closer look at why LiDAR is critical to rail right of way and track documentation.

Rising maintenance costs

One of the big reasons why utilizing a LiDAR mapping system is important to the railroad industry is cost. The amount of money spent manually tracking railroad right of way is steadily increasing, and budgets are not expanding in response. This leads to discrepancies between the cost of operations and the operations budget. Over time, this can lead to poorly maintained tracks and the potential for costly repairs in the not-so-distant future.

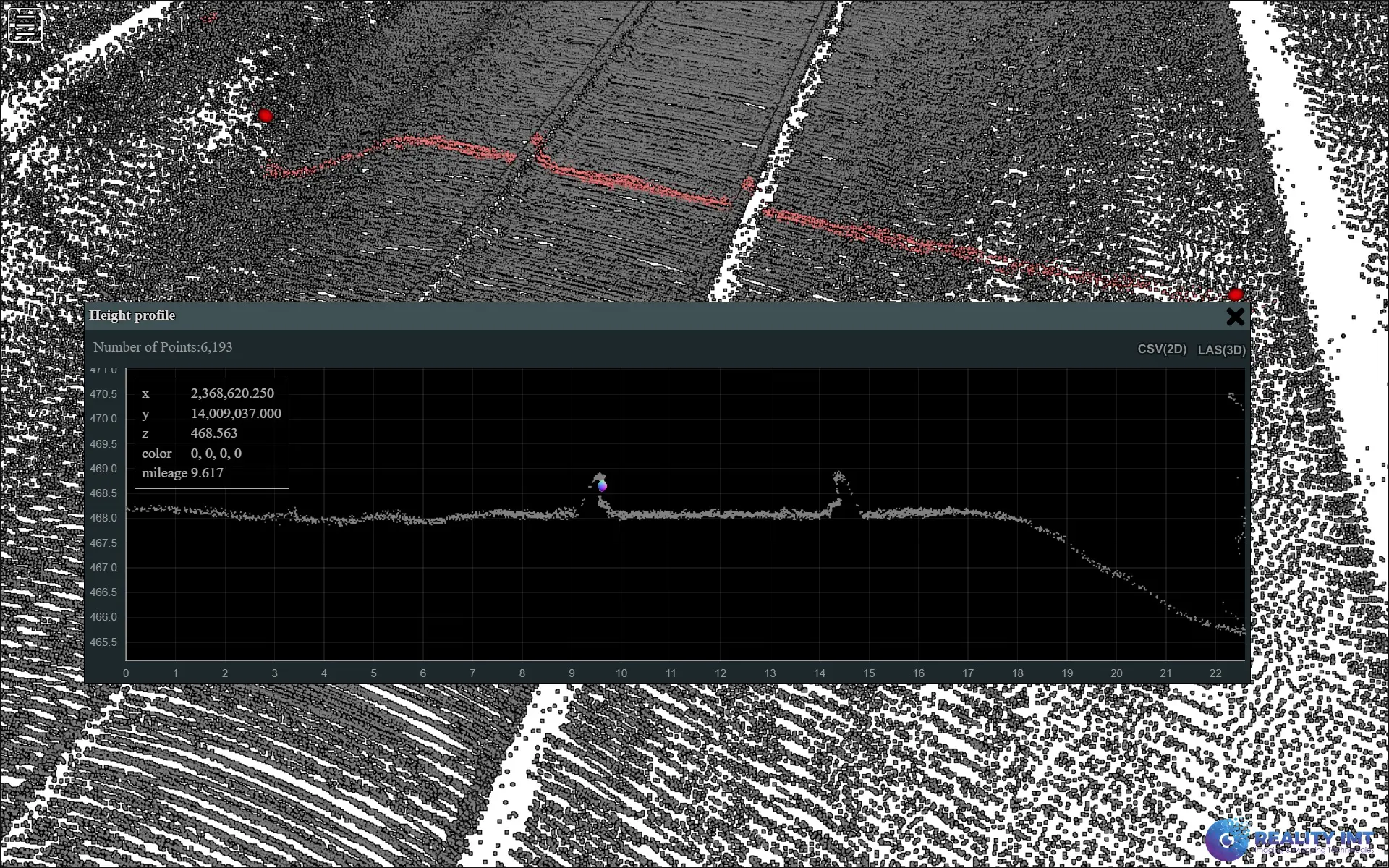

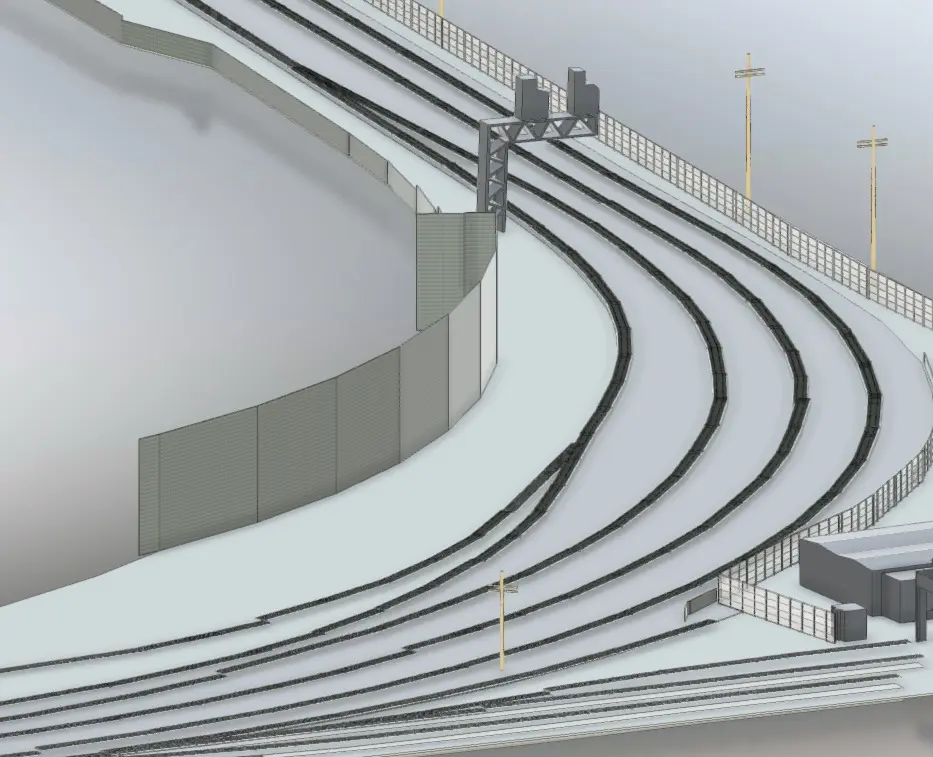

LiDAR is the ideal solution to the rising costs of railway maintenance. Instead of hiring a team of field agents to travel the country manually mapping extensive railroad tracks, we deploy a hi-rail vehicle – a vehicle that works both on the highway and on railroad tracks – to collect 3D survey data as it travels. Once we have the data we need, we post-process the 3D imagery and measurements to create the equivalent of a “digital footprint” of the entirety of the right of way, including all above-ground assets. We also extract the following from the data:

- Mileposts

- Geometry

- Signals

- Ditch profiles

- Ballast profiles

- Grade crossings

Once all of the useful data has been analyzed and post-processed, we deliver it to clients in either CAD or GIS format. Reality IMT also provides clients with an interactive map to help visualize the collected data. This map can be shared across multiple teams and multiple locations.

LiDAR mapping offers great value for cost by avoiding the potential errors made by manual teams as well as the expenses they incur. And because it allows our clients to keep their tracks in excellent condition, they avoid the expensive repairs that occur when something breaks down.

Disruption to service

Our LiDAR 360-degree mapping system also helps prevent disruptions to service. Instead of closing a section of the railway down in order to fully survey it, LiDAR’s hi-rail vehicles can survey at traveling speed. Not only this, but our clients appreciate their ability to identify potential issues before they become big problems that shut down their tracks.

Whether you are hoping to stay ahead of costly repairs or simply want a clear map of your railway right of way, LiDAR 360-degree mapping is an excellent solution.